Continuous Stirred Tank Reactor Simulation Using Aspen HYSYS

|

| Continuous Stirred Tank Reactor |

In the chemical

industry, reactors are important equipment as a medium for reactions to produce

products. Aspen HYSYS is a process simulation that is very useful for a

chemical engineer. ASPEN HYSYS helps to understand the process, identify the

advantages and disadvantages of the process and calculate the energy

requirements needed when operating.

Modeling the

Reactor by simulating it on ASPEN HYSYS is not too difficult as long as we

understand well how the basic principles of a reaction occur. Previously we

have simulated a Plug Flow Reactor (PFR) type reactor on this page. This

time we will simulate a Continuous Stirred Tank Reactor (CSTR) type reactor,

hopefully, chemical engineering friends can follow it well and can practice it

themselves.

Introduction

Continuous stirred

tank reactor assumes mixing occurs perfectly throughout the reactor volume and

outlet conditions are expected to be the same as conditions inside the reactor.

CSTR reactors are generally run continuously and are also used for homogeneous

liquid-liquid reactions. Residence time affects the resulting reaction

conversion. In the Continuous Stirred Tank Reactor, the residence time of the

reactants is determined by the flow rate (discharge) of the incoming reactants

and the outgoing products. CSTR residence time is very limited so it is

difficult to achieve high reactant conversion, for this reason, a large enough

reactor volume is needed to get the desired reaction conversion.

Case example

Below is a case

that we will use as an example in simulating a Continuous stirred tank reactor

(CSTR).

2-Butene is a

four-carbon alkene that exists as two geometric isomers: cis-2-butene and

trans-2-butene. The irreversible liquid phase isomerization reaction with

1st-order reaction kinetics is shown below. It is desired to determine the

residence time required to reach 90% reaction conversion in a continuous

stirred tank reactor. Assume steady state

Homogeneous reaction

1st order reaction kinetics rA

= kCA, k = 0,23min-1 = 0,0003833 s-1

Simulation completion

Open the Aspen

HYSYS program. Select New to create a new simulation

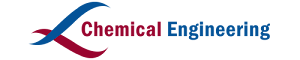

Create a component

list. In the Component List folder select Add. Search for C4H8

then select cis2-butene and tr2-butene and add them to the

component list.

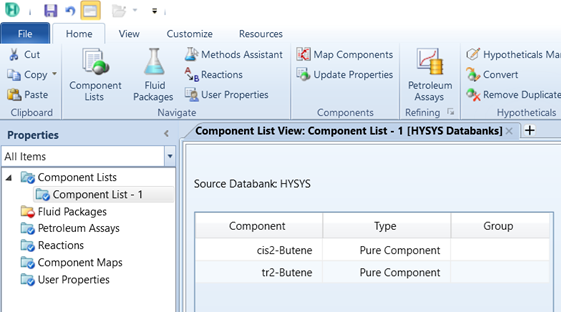

Define the property package, in the Fluid Packages folder select Add. Select NRTL as the property package

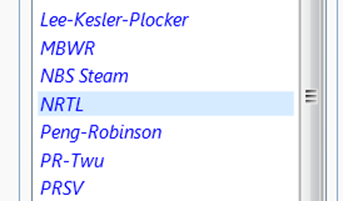

Define the

reaction. In the Reactions folder select Add to create a new

reaction. In Set-1 select Add Reaction and click Kinetic Reaction.

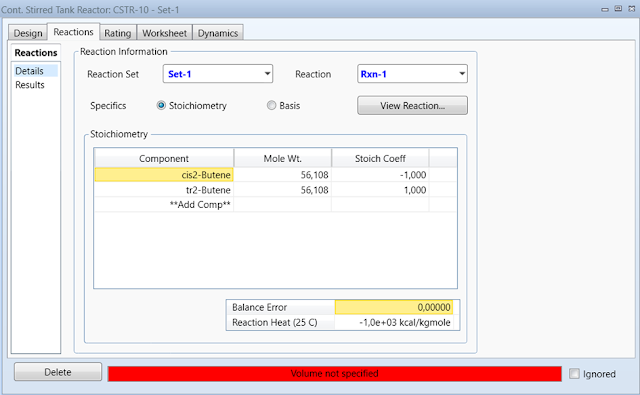

Double-click Rxn-1

to define the kinetic reaction. Add cis2-Butene and tr2-Butene in

the component column. Define the Stoich Coeffs of -1 and 1.

In the Forward Reaction section define the value of A to be 0.23000,

for the values of E and B define 0. Make sure the Base

units and Rate Units are in ibmole/ft3 and ibmole/ft3-min

respectively.

After that, exit

the kinetic reaction window. Click the Add to PF button and select Base-1.

Next, enter the

simulation by clicking simulation on the bottom left screen.

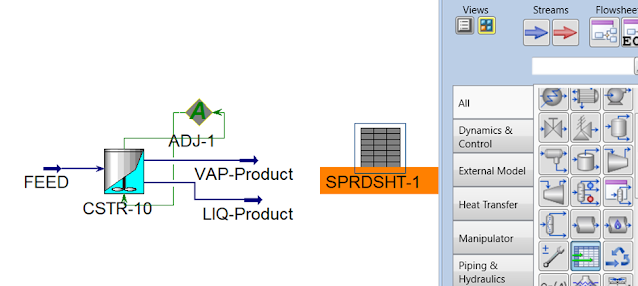

Select reactors

then add Continuous Stirred Tank Reactor to the flowsheet.

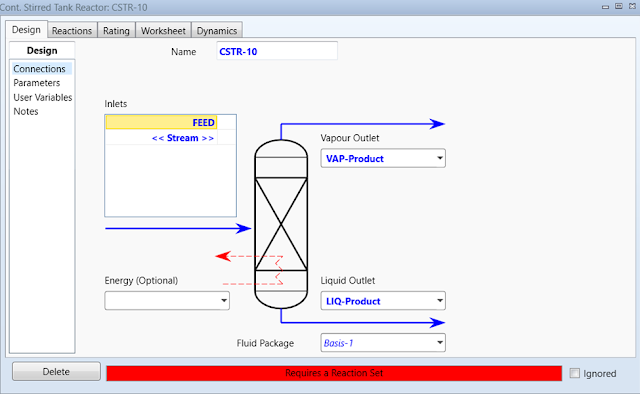

double click the reactor

(CSTR-10). Define the Inlet stream to be FEED, a Vapour Outlet stream

called VAP-Product, and a Liquid Outlet stream called LIQ-Product.

On the reactions

tab select Set-1 for Reaction Set.

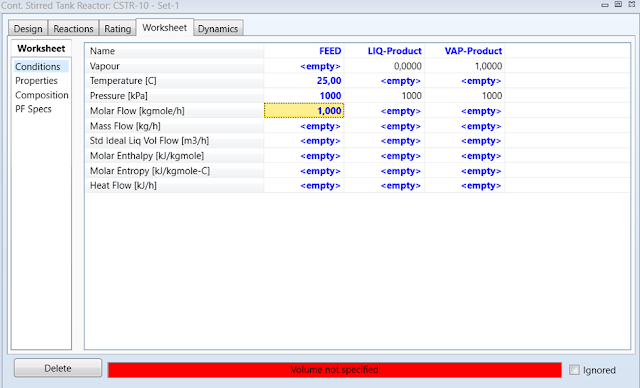

Next to the Worksheet

tab. Define the FEED stream and enter the values of Temperature 25oC,

Pressure 10 bar (1000 kpa), and Molar Flow 1 kgmole/h.

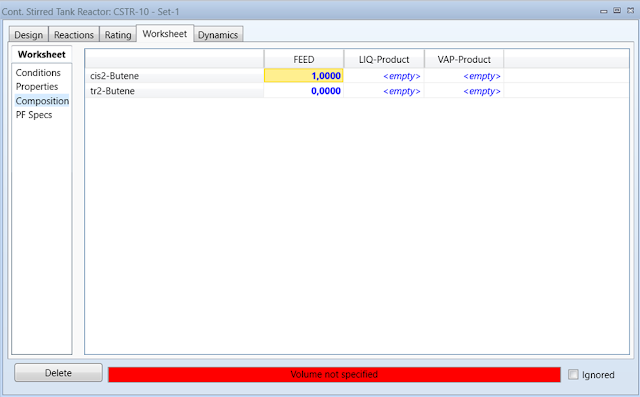

Click the Composition

tab and define Mole Fraction 1 for cis2-Butene.

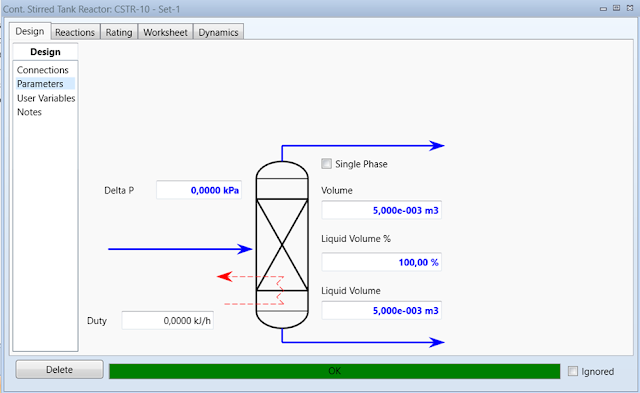

On the Design

tab in the Parameters menu enter a volume value of 0.005 m2

and Liquid Volume 100%. This volume value is only a starting

guess, we will later add adjust blocks to determine the actual volume required

to achieve 90% reaction conversion.

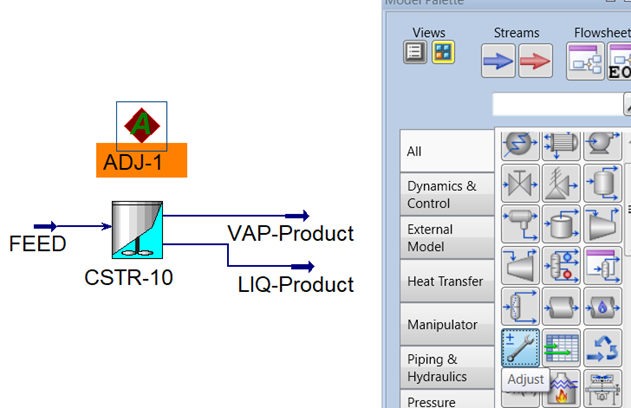

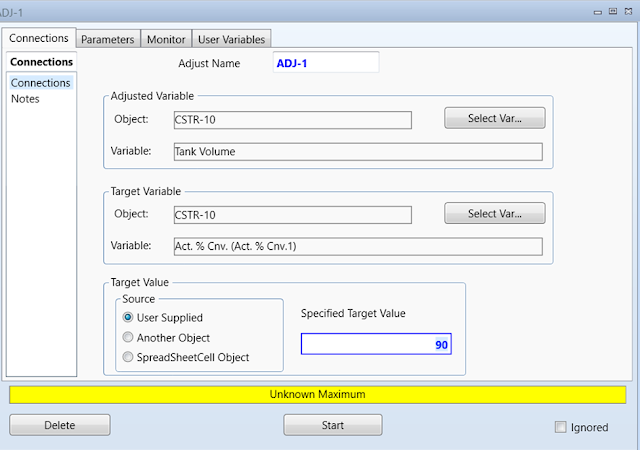

Add Adjust

block to the flowsheet from Model Palette Double-click on the Adjust block (ADJ-1),

we will adjust the correct volume value to get 90% reaction conversion. In the Adjusted

Variable select the Tank Volume of CSTR-10. For the Targeted

Variable select Act. % Cvn. of CSTR-10. Enter a Specified

Target Value of 90.

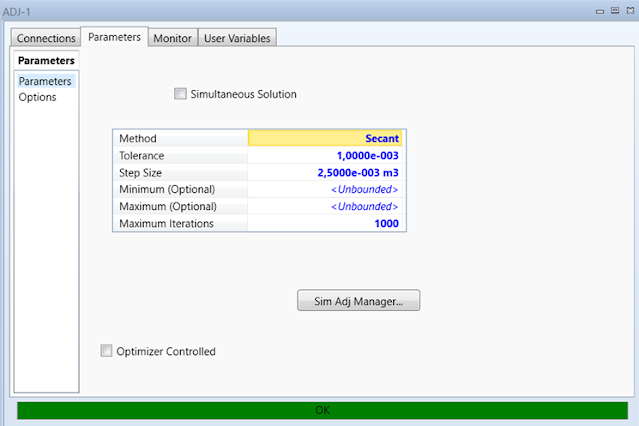

On the Parameters

tab change Maximum Iterations to 1000. Click Start to

start the calculation until the word OK appears on the green background.

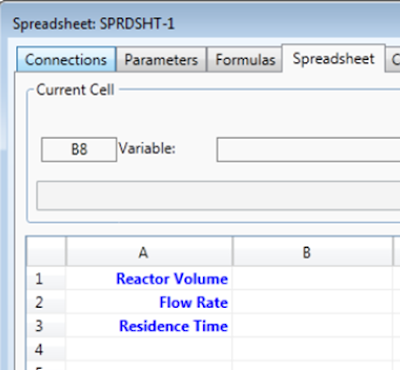

Create a

spreadsheet to calculate the residence time. Add a Spreadsheet to the

flowsheet from the Model Palette.

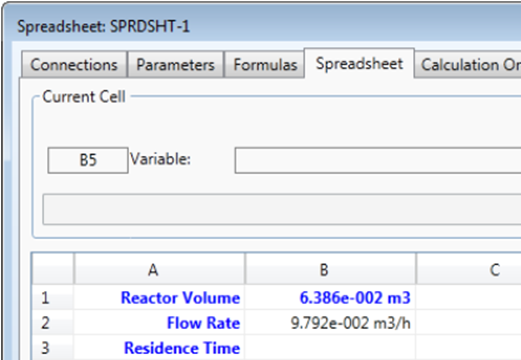

Double-click the

spreadsheet (SPRDSHT-1). In the Spreadsheet tab, enter the

following text in cells A1, A2, and A3

Right-click on cell

B1 and select Import Variable. Select the Tank Volume of CSTR-10.

Right-click on cell B2 and select Import Variable. Select the Actual

Volume Flow of the LIQ-Product stream.

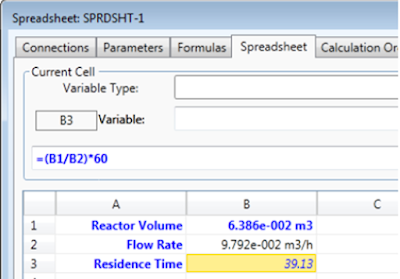

In cell B3 enter the following formula: = (B1/B2)*60. This will display the residence time in minutes

The residence time

is 39.13 minutes, This suggests that if we want the Continuous Stirred

Tank Reactor to get a 90% reaction conversion then we must design the reactor

with a residence time of 39.13 minutes.

If you find this blog useful, please share it with your social media colleagues, so that other chemical engineering colleagues also feel the same benefits from this blog.