How Does A Knockout Drum Work

In industry, the process of separating and cleaning gas streams from contaminants and liquids is an important stage in maintaining the smooth operation and safety of equipment. One of the key devices that perform this important task is the knockout drum. In this article, we will understand what a knockout drum is, why it is so important, how it works, and its key components.

What is a Knockout Drum?

A knockout drum is a tank or

container specifically designed to remove solid particles, liquid vapors, and

liquids from a gas stream. The name "knockout" refers to the physical

process in which particles or condensed liquids are "kicked" or

"ejected" from the gas stream. These devices are used extensively in

a variety of industries, including oil and gas, petrochemicals, power

generation, and more.

The function of Knockout Drum

The primary function of a

knockout drum is to clean the gas stream of contaminants that can damage

equipment or reduce product quality. Knockout drums also protect more sensitive

downstream equipment from damage caused by contaminants such as solid particles

or liquids.

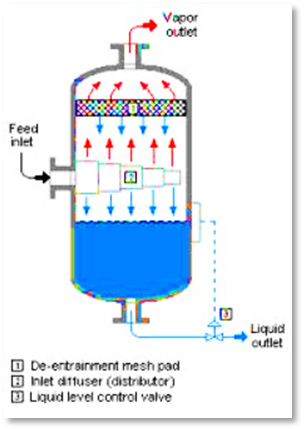

How Knockout Drum Works

Knockout drums function by

removing contaminants from the gas stream. First, the gas stream containing

contaminants enters the knockout drum through the intake pipe. As the gas

enters the drum, its velocity is abruptly reduced, causing contaminants such as

solid particles or liquid vapors to become heavier. Inside the drum, separation

occurs between the gas phase and the liquid phase. The heavier solid particles

or liquids separate and fall to the bottom of the drum. Subsequently, the

separated liquid is discharged from the bottom of the drum through the liquid

discharge pipe, while the gas that has been cleaned of contaminants is

discharged from the top of the drum through the gas discharge pipe. In this

way, the knockout drum cleans the gas of impurities and keeps the gas used in

industrial processes cleaner and safer.

Components of a Knockout Drum

Shell (Drum Body): This is the

main body of the knockout drum, tubular or spherical. The shell is where the

main phase separation occurs.

Mist Extractor. A mist

extractor is a component that helps separate liquid vapor or fine particles

from the gas stream.

Liquid Outlet. The liquid

separated from the gas stream is removed through the liquid outlet pipe at the

bottom of the knockout drum.

Gas Outlet. Clean gas that

has gone through the separation process is removed through the gas outlet pipe

at the top of the knockout drum.

Level Control. Level

control is a device that monitors and regulates the liquid level in the

knockout drum.

Pressure Relief. A

pressure relief is used to protect the knockout drum from overpressure.

Manhole. A manhole is an

inspection hole that allows access into the drum for maintenance and cleaning.

Supports. Knockout drum

must be supported by strong supports to maintain its stability.

Drain. A drain is used to

discharge the liquid collected at the bottom of the knockout drum.

Conclusion

Knockout drums are key components in industries that require gas and liquid separation. Its proper use helps ensure that the gas stream is clean of contaminants that could damage equipment or products. Therefore, knockout drums are important devices that help maintain smooth industrial operations and protect company assets. Thus, its role in the industrial world is indispensable. With a better understanding of knockout drums, we can appreciate the importance of these devices in keeping industrial processes running smoothly.