Simulating the use of distillation shortcuts in Aspen HSYYS

|

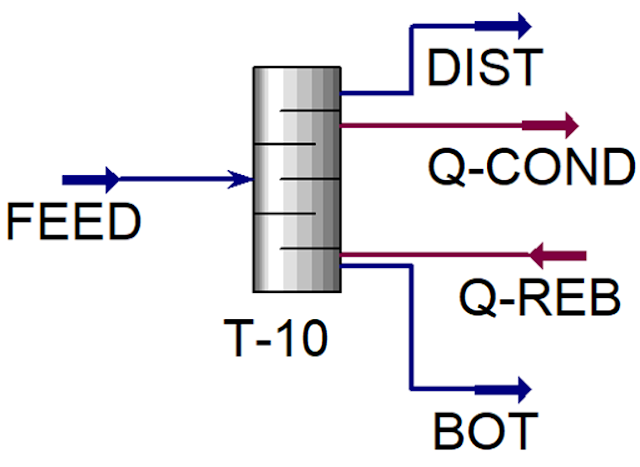

| Distillation Column |

Welcome to chemical

engineering expert! If you are interested in how the process of separating

components in an industry is done, then you have come to the right place. In industry,

we often use distillation columns to separate mixtures into their components.

However, did you know that designing a distillation column doesn't always

require complex calculations and long hours?

This is where

Shortcut Distillation comes to the rescue! Shortcut distillation is a method

used to quickly design distillation columns. One software that is very popular

in the industry is Aspen HYSYS. HYSYS provides excellent capabilities to

analyze and design distillation systems using shortcut distillation.

The utilization of

distillation shortcuts in HYSYS allows users to quickly model distillation

separations with little-known information. The distillation shortcut block performs a short

calculation based on the Fenske-Underwood equation for a simple reflux tower.

Fenske-Underwood is a method used in distillation column design to estimate the

number of trays (in a tube distillation column) or packing height (in a packed

distillation column) required to achieve the desired separation between

components in a mixture. The method is named after two chemists, Richard E.

Fenske and Samuel L. Underwood, who developed the method in 1932.

The

Fenske-Underwood method is based on an equation that relates the number of

trays or packing height to the separation efficiency and concentration

difference between the two separated components. This equation is commonly

known as the Fenske equation or the Fenske-Underwood equation. This equation

simplifies complex and complicated calculations into a more user-friendly

approach. In the Fenske-Underwood equation, the key factors affecting the

calculation are the separation efficiency (a value between 0 and 1 that

describes the extent to which component separation occurs) and the difference

between the separated components' relative volatility factors (R). The relative

volatility factor describes the difference in volatility between two components

in a mixture and is an important parameter in distillation.

Using the

Fenske-Underwood equation, you can estimate the number of trays or packing

height needed to achieve the desired separation based on the separation

efficiency and the difference in relative volatility factors. This is very

useful in the initial design of a distillation column and helps in determining

the overall column dimensions and performance. The Fenske-Underwood method has

become a commonly used approach in distillation column design and an important

part of software tools such as HYSYS to design efficient and optimized

distillation systems. By utilizing this method, engineers and designers can

estimate the number of trays or packing heights required in a distillation column before

performing more detailed calculations and more complex simulations.

Heavy and Light keys

In two-component

distillation, the column splits the feed so that one component is enriched in

each outflow. In multi-component distillation, more components are involved, so

for separation, multiple components are enriched in one distillation column

outflow. What are light and heavy keys?

Light key: lighter

component or component with a lower boiling point. Defined as the component that

is lighter than the component in the bottom product of the distillation column.

Heavy key: heavier

component or component with a higher boiling point. Defined as the heaviest

component than the component in the top product of the distillation column.

*Notes: Light and

Heavy keys depend on the components in the stream.

The determined

reflux ratio can be used to calculate the vapor and liquid passage rates in the

enriching and stripping sections, condenser duty and reboiler duty, the ideal number of trays,

and the optimal

feed location. Column distillation shortcuts are only estimates of column

performance and are limited to simple reflux columns. For more realistic

results and closer to the actual field, use the distillation column. Below we present an example

case that can be used as practice material for our material this time.

Problem

A stream containing

68.5 wt% ethylene and 31.5 wt% ethane with a total flow rate of 7.3 million

ib/day must be separated. Establish a reasonable starting point for a more

detailed design including an estimate of the theoretical number of stages and

reflux ratio required to achieve 99.9% ethylene recovery and 99.0% ethane

recovery.

In solving these

equations, the user must enter the virtual components that are light key and

heavy key and the recovery of each of these components, the pressure in the

condenser and reboiler, and the reflux ratio. These equations are good crew

ratios, but the shortcut column is not an accurate calculation, it does not

directly use thermodynamics to solve for the reflux ratio or the number of

stages required.

Aspen HYSYS

Solution

Open a new case in

Aspen HYSYS

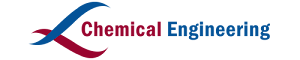

Enter the component

list involved in the case. In the Component List folder select Add,

then add Ethane and Ethylene to the component list. You may have

to type "ethene" to find Ethylene.

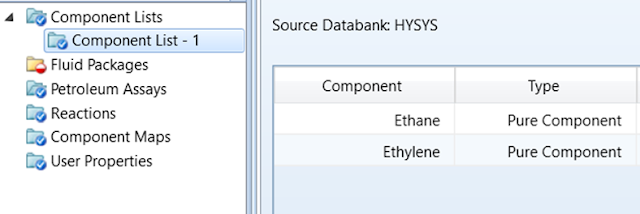

Define the fluid

package used. In the Fluid Packages folder select Add and select Peng-Robinson

as the package property.

Next, we can start the

simulation by clicking Simulation on the bottom left screen.

Add Short Cut Distillation model to Flowsheet

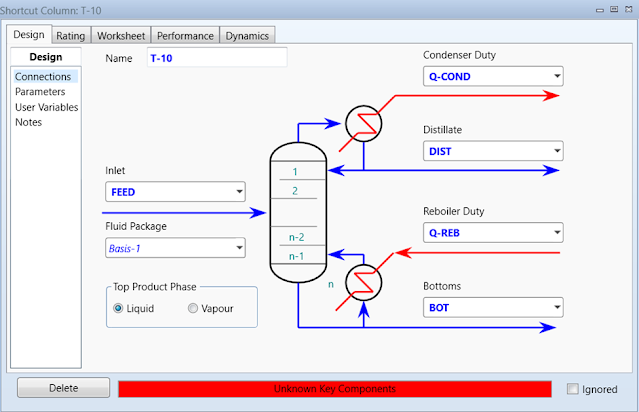

Double click on

colom (T-10). Define Inlet flow as FEED, Condenser Duty

as Q-COND, Distillate as DIST, Reboiler Duty as Q-REB,

and Bottoms as BOT. Check the Liquid radio under Top

Product Phase, which defines the total condenser.

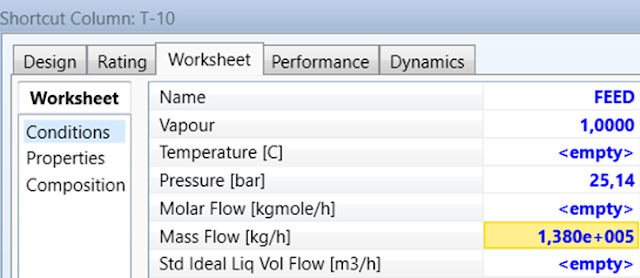

Define the feed stream

conditions. Go

to the Worksheet tab and enter Vapor Fraction 1, Pressure 350 psig (25.14 bar),

and Mass Flow 7,300,000 lb/day (1.38e+005 kg/h).

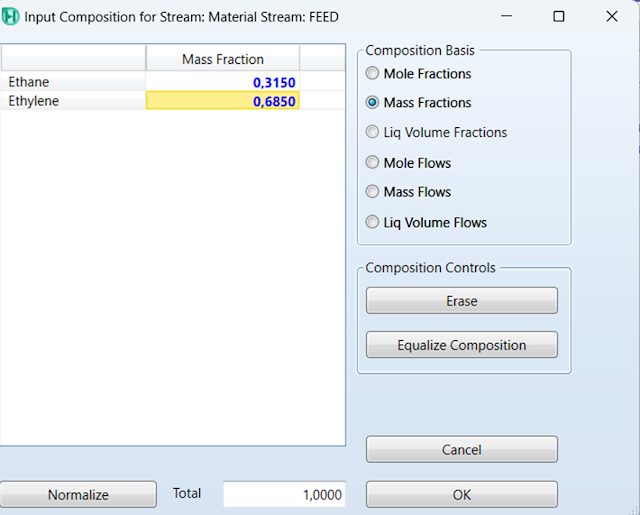

In the Composition

section enter the Mass Fraction values of Ethane and Ethylene

as 0.315 and 0.685 respectively. the feed stream will be

finalized.

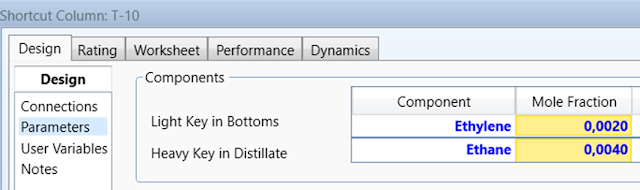

Next, go to the Parameters

section located under the Design tab in the Shortcut Column window.

Using the percentage recovery specified in the problem statement along with a

simple mass balance, it can be determined that the mole fraction of ethane in

the distillate stream will be 0.004 and the mole fraction of ethylene in

the bottom will be about 0.002. Enter these values into the Component grid in the Parameter form.

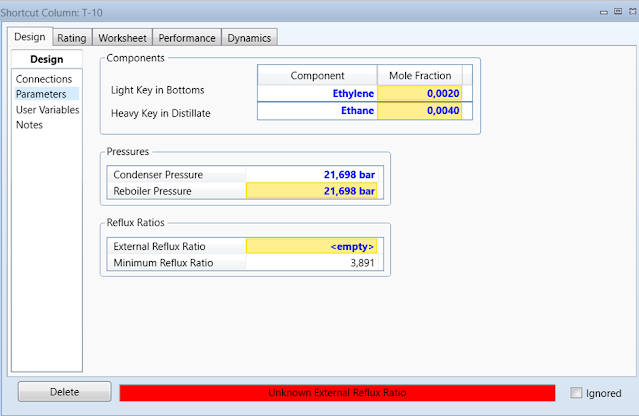

Enter the Condenser

and Reboiler pressure values of 300psig (21.698 bar) each. You

can see that HYSYS has now calculated the Minimum Reflux Ratio required to

complete the specified separation with an infinite number of stages.

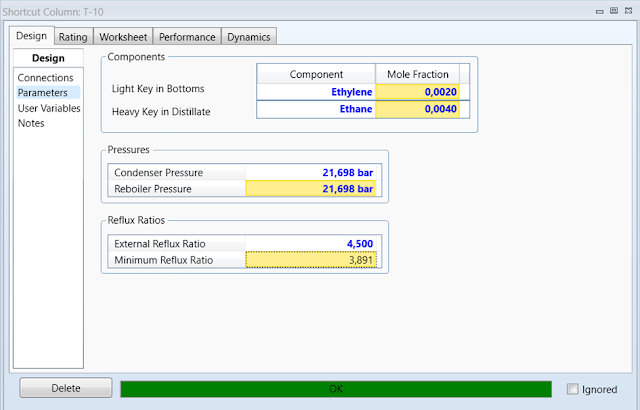

Now that you can

enter the Reflux Ratio, Shortcut Column will calculate the number of stages,

feed stage location, material and energy streams, and condenser and reboiler

temperatures. For example, enter 4.5 as the External Reflux Ratio.

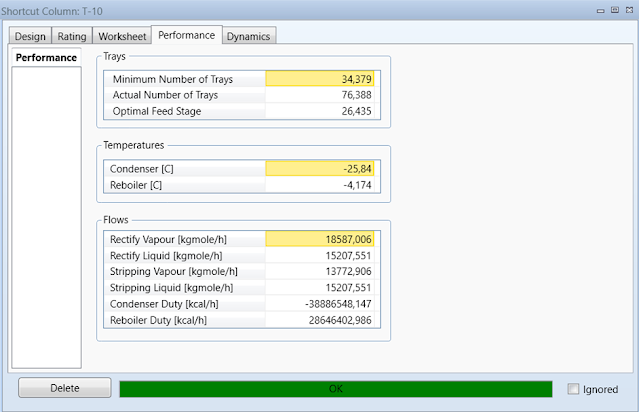

On the Performance

tab, you will see the results as follows.

Conclusion

Estimation using

Shortcut Columns can be done very quickly, even for complex distillation

systems. The results can then be used as a starting point for more complex

analysis, such as with complicated distillation models.