Refrigerant system simulation using Aspen HYSYS

The refrigeration

system simply works by regulating the pressure and also the temperature of the refrigerant. To simulate

the working mechanism of this refrigerant system, we can do it with the help of

Aspen HYSYS. But before going further to simulate it, we need to know first how

the working principle of the refrigerant system. Therefore, we need to get

acquainted with this refrigerant system.

Introduction

Refrigeration

systems are often encountered in our daily activities, a simple example is the

use of Air Conditioner (AC). In the case of an Air Conditioner (AC), the refrigeration system

uses refrigerant to extract heat from the process circulation fluid and then

discharges it into the atmosphere. The basic principle of a refrigerant system

is the compression and phase change of the refrigerant from gas to liquid and

back again to gas. The repetitive process of changing the refrigerant from gas

to liquid and then back again to gas is called the refrigeration cycle. Changing the

physical state of a compound (from gas to liquid or vice versa) is the most

efficient method of absorbing or expanding energy.

The four main

components in the refrigeration cycle are the evaporator, compressor, condenser, and expansion valve.

1. Evaporator

Is a device that

transfers heat from the process fluid to the refrigerant which causes a phase

change (evaporation).

2. Compressor

The compressor is

the core component of the refrigerant system that works by heating the refrigerant gas causing

the pressure and temperature of the refrigerant gas to increase and then

circulating it through the process refrigerant system. Increased refrigerant gas pressure also has an impact on

increasing its temperature.

3. Condenser

The condenser lowers

the temperature of the refrigerant gas vapor to condense into a saturated

liquid, aka condensation. As a result of condensation, the refrigerant becomes

a high-pressure, low-temperature liquid.

4. Expansion valve

The expansion valve

works by lowering the pressure of the liquid refrigerant. As a result of this

pressure drop, it also has an impact on the decrease in refrigerant

temperature. Refrigerant becomes low pressure and low temperature At the

expansion valve

For the refrigeration system to work properly there must be four main components. An example of the direct application of the use of refrigerant systems in industry is the ammonia industry. In the ammonia industry, the refrigerant system is used to increase ammonia products.

|

| Refrigerant system in ammonia plant |

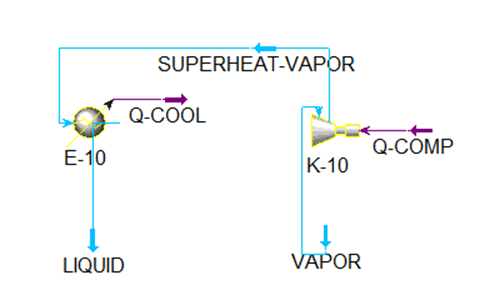

Case example and simulation solution

Determine the cooling capacity of 300 kgmole/h of CFH2-CF3 when allowed to expand from 10 bar to 1 bar.

Create a new

simulation in Aspen HYSY

Enter the Component

list by opening the Component Lists folder select Add. Add 1,1,1,2-tetrafluoromethane to the component list.

Define the Fluid Package used, and select Add. Then select NRTL as the property package

Add Compressor,

Cooler, Heater, and Valve to flowsheet

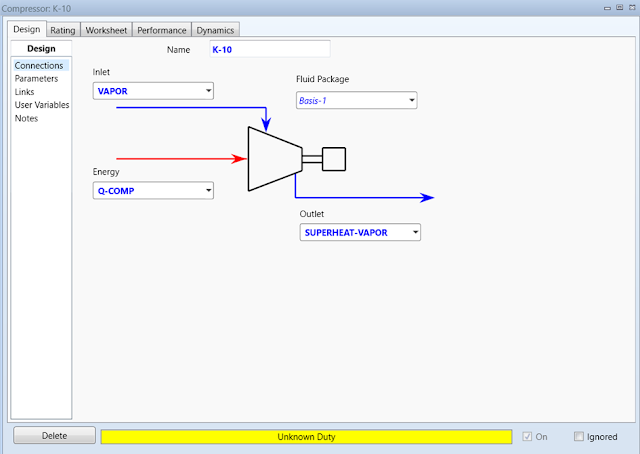

Double-click on the compressor (K-10).

Define Inlet Stream as VAPOR, Outlet as SUPERHEAT-VAPOR,

and Energy as Q-COMP.

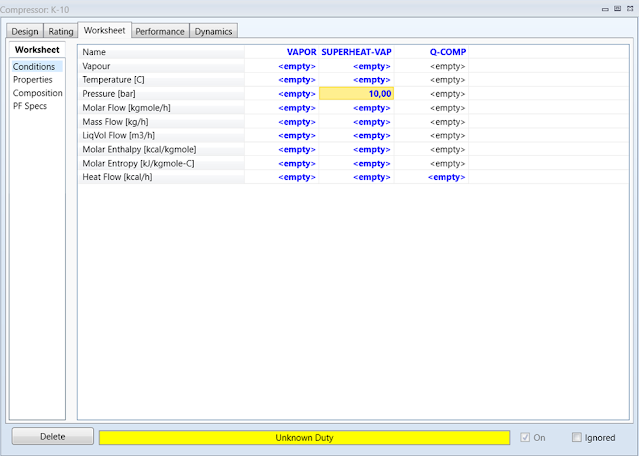

On the Worksheet

tab, enter a Pressure value of 10 bar

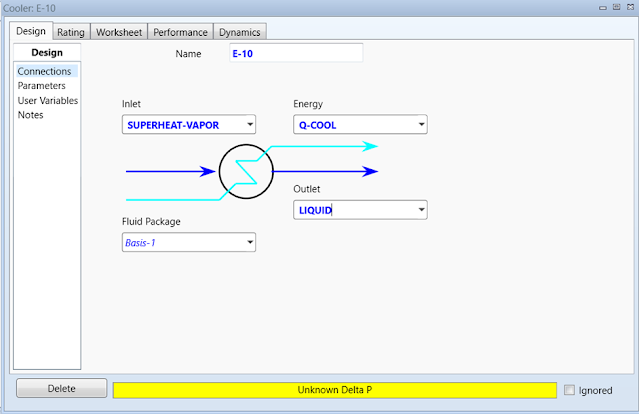

Double-click Cooler (E-10). Define Inlet Stream as SUPERHEAT-VAPOR, Outlet Stream

as LIQUID, and Energy Stream as Q-COOL.

In the Worksheet

tab, enter the outlet Temperature value of 30oC. in

the Parameter section under the Design tab enter the Delta P value = 0

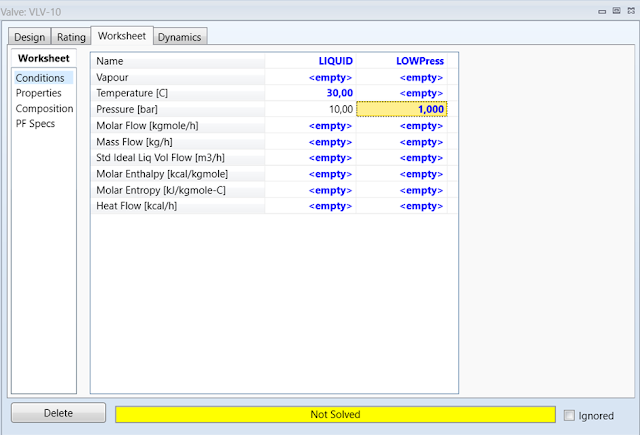

Double-click valve (VLV-10). Define Inlet

Stream as LIQUID and Outlet as LOWPress

On the Worksheet tab enter

the outlet value Pressure = 1

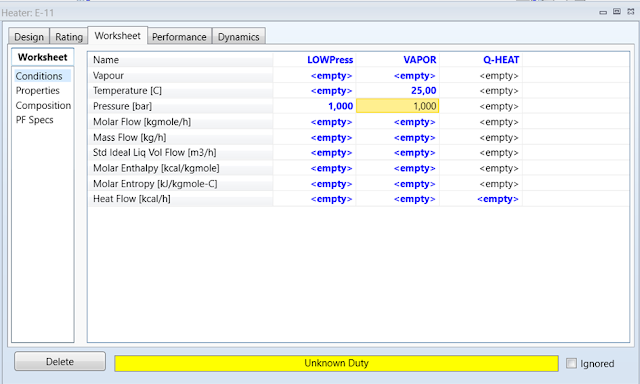

Double-click on the heater (E-11). Define Inlet Stream

as LOWPres, Outlet Stream as VAPOR, and Energy Stream

as Q-HEAT.

In the Worksheet

tab, enter the outlet Temperature value of 25oC. in

the Parameters section under the Design tab enter the Delta P

= 0

Now we have to determine the molar Stream rate and refrigerant composition. Double-click any Stream, for example, Vapor Stream. Enter a Molar Flow of 300 kgmol/hr. In the Composition form specify Mole Fraction 1 for the refrigerant.

HYSYS will complete

the calculation

Check results. To

see the cooling capacity of this refrigeration loop, double-click the Q-COOL Energy Stream. This

stream is removing 1,925e+006 kcal/hour, or about 534.72 kcal/second

Conclusion

Refrigeration is the process by which heat moves

from a cooler location to a hotter location using external work (e.g. a

compressor). We know that the vaporization of liquids requires heat. If no external heat is

available, the heat will come from the liquid itself by reducing its

temperature.

If you find this blog useful, please share it with your social media colleagues, so that other chemical engineering colleagues also feel the same benefits from this blog.