Reactor Types in Aspen HYSYS

In the world of chemical

engineering, process simulation is an important step in designing, analyzing,

and optimizing various chemical processes. Aspen HYSYS is a very powerful and

widely used industrial process simulation software worldwide. One important

aspect of process simulation is the modeling of a chemical reactor that matches

the type of reaction being observed. Below, we will discuss some of the reactor

types that you can encounter within Aspen HYSYS:

1. Conversion Reactor

Conversion reactor simulation in

HYSYS is done by setting the conversion value of a reaction. This type of

reactor is easier to achieve convergence compared to CSTR and PFR reactors.

Users can use it to calculate how much reactants can be converted into products.

Conversion reactors can also be used for a series of continuous reactions,

where the products in the previous reaction can become reactants in the next

reaction. We will make an example of a case that uses a conversion reactor.

Hydrogen production from

hydrocarbons has increased significantly in the last decade. The conversion of

fuel (methane gas) to hydrogen can take place by partial oxidation. This method

involves burning methane with oxygen to produce carbon dioxide and hydrogen, as

shown in the following reaction:

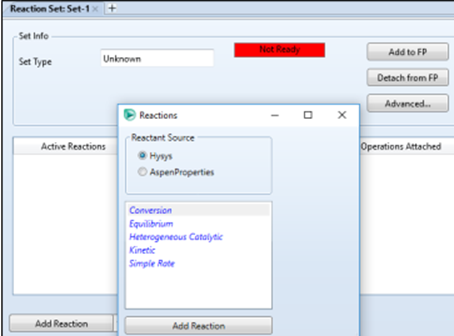

It is known that the conversion

of reaction 1 is 40% (CH4 basis) and reaction 2 is 60% (CH4 basis). Make a

simulation of the above reaction with the specifications of the reactants

entering the reactor as follows.

|

Spesifikasi |

Metana |

Oksigen |

|

Suhu (oC) |

25 |

25 |

|

Tekanan (bar) |

2 |

2 |

|

Laju Alir (Kmol/hr) |

100 |

100 |

|

Mol Fraksi |

||

|

Metana |

1 |

0 |

|

Oksigen |

0 |

1 |

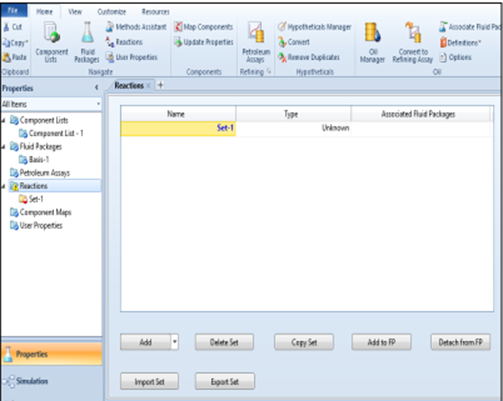

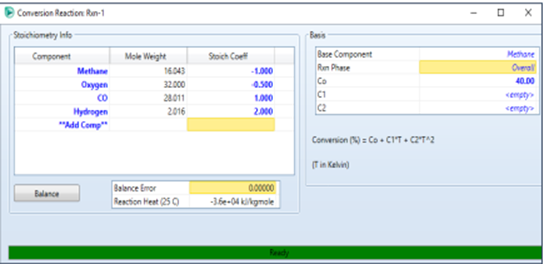

Open the HYSYS Apsen Program and

select all components involved in the process as in the reaction. Use Peng-Robingson

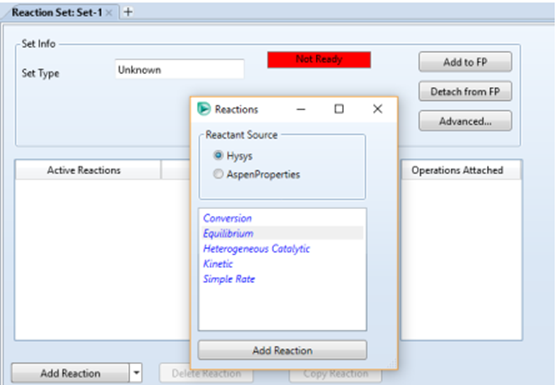

Fluid Package. Click on the "Reaction" option

click Add, then Add

Reaction, and select Conversion in the reactions window.

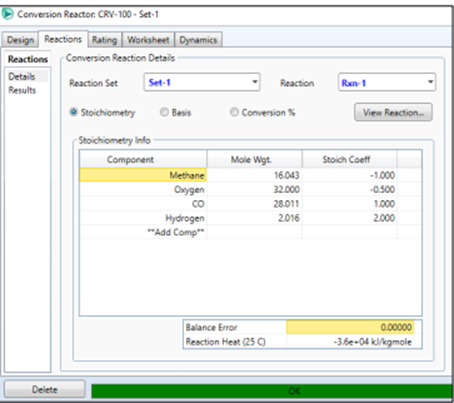

Double-click on RXN-1,

then we fill in the components, stoichiometry, and conversion of

the reaction we want to achieve.

After both reactions are added,

click on the Add to FP → Add Set to Fluid Package option, and the

notification changes from yellow to green (Ready), then enter the simulation

page.

Create a stream according to the specifications

above, then connect it to the conversion reactor (which can be found in the

column section).

Double click on the reactor icon

→ Reaction, In Reaction Set select Set-1.

To see the reaction output

product, click Worksheet→ Condition or Composition.

2. Equilibrium Reactor

An equilibrium reactor is a

reactor for modeling equilibrium reactions. The outflow from this reactor is in

a chemically and physically balanced state. The number of reaction sets entered

in this reactor operating model can be unlimited, which will be completed by

HYSYS simultaneously or sequentially. In this reactor model, each component or

mixing process does not have to occur ideally, because HYSYS can calculate the

chemical activity of each component in the mixture based on the fugacity of the

mixture or pure component.

Case example

A feedstock of pure n-butane (100

kmol/hr) is cracked at 750 K and 1.2 bar to produce olefins. Only two reactions

have favorable equilibrium conversions at these conditions:

If these reactions reach

equilibrium, what is the product composition? Use Peng-Robinson Fluid Package

The steps in completing this simulation are

the same as working on the conversion reactor, only different in the selection

of the reaction type!

Add reactions in the same way as

the conversion reactor, but this time select Equilibrium reaction.

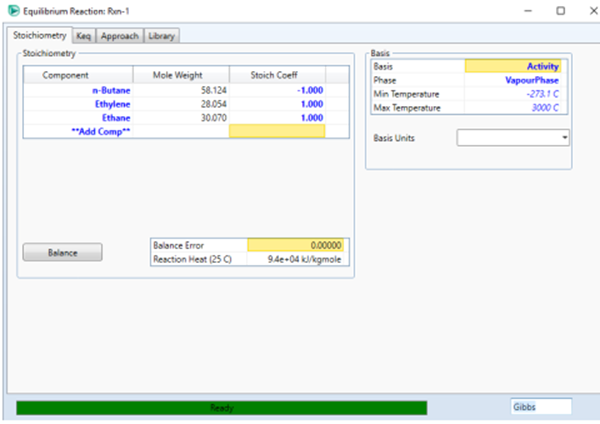

Define the stoichiometry of each

component as below. Also, define reaction 2 in the same way. When finished

click Add to FP

and continue with the simulation process.

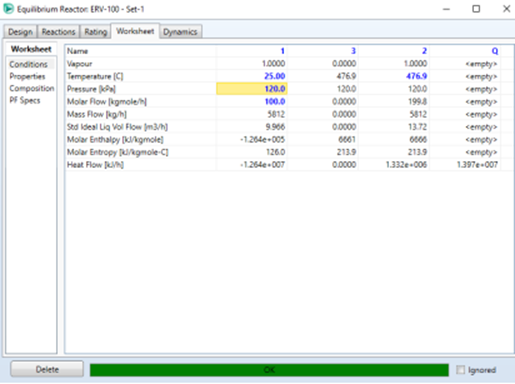

Define the operating conditions

used on the Worksheet tab as shown below

3. Ideal CSTR Reactor (Continuous Stirred-Tank Reactor)

CSTR reactors are one of the most

commonly used reactor types in chemical process simulations. In this reactor,

chemical reactions occur in a tank with continuous mixing. The reactants are

added to the tank and mixed continuously. The advantage of this reactor is that

the temperature and concentration can be kept stable. However, this reactor is

more suitable for reactions with slow reaction kinetics.

The CSTR reactor assumes perfect

mixing in each part of the reactor volume and the outflow conditions are the

same as the conditions inside the reactor. Reactions that can be used for

modeling this type of reactor are kinetic reactions and heterogeneous catalysis

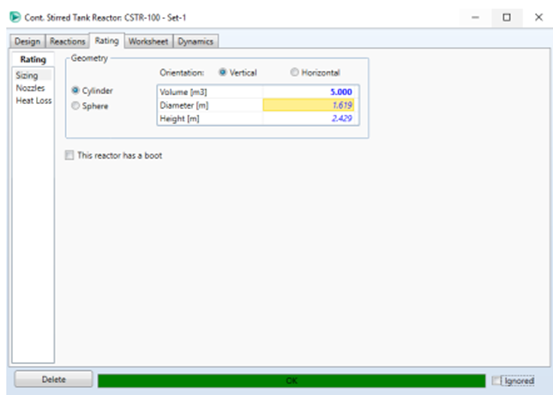

In the CSTR reactor, the conversion of the reactor is also affected by the

reactor volume, so volume geometry information must be given. Depending on the

reactor geometry, at least 2 pieces of information must be provided, either

volume, height, or diameter.

Required input data

Propylene Glycol can be produced

from the reaction between Propylene Oxide and water as below:

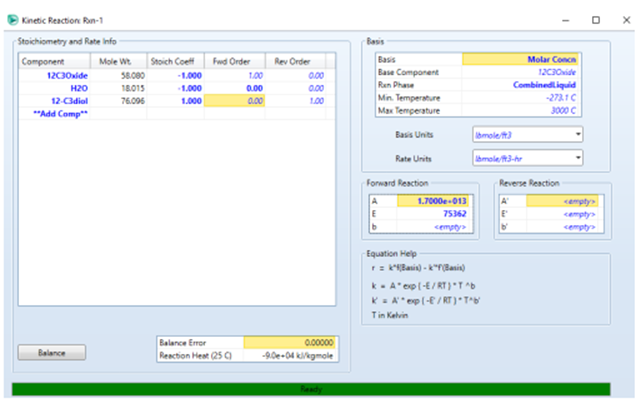

With the following reaction

kinetics data

with the base unit in lb mol/ft3

and the rate unit in lb mol/ ft3 hr. Propylene Oxide (150 kmol/hr) and water

(200 kmol/hr) at 25 C and 101.3 kPa. enter the reactor through 2 different

streams which will then be mixed using a mixer. The CSTR reactor operates at a

pressure of 101.3 kPa and 25°C with a volume of 5 m3. What is the rate of

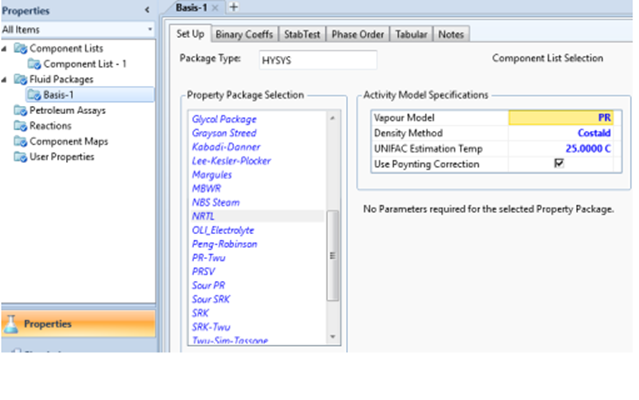

Propylene Glycol produced? Select UNIQUAC as the fluid package.

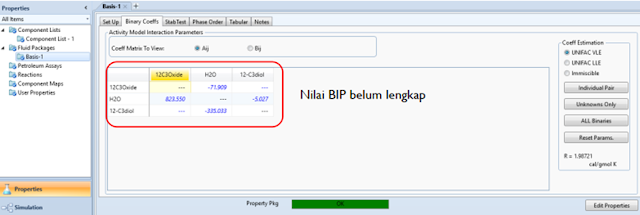

Estimation of Binary Interaction

Parameters that are not yet available.

Estimation of unavailable Binary

Interaction Parameters

- Unavailable BIP values can be

estimated with 3 method options

- UNIFAC VLE, LLE or immicisble

solution.

- In this case, we choose UNIFAC

VLE

- Click on unknowns only

Provide reaction input by first

selecting the reaction type "Kinetics", and input as follows

The forward order value for H2O

is 0 because H2O is given in excess so the reaction rate

only depends on the concentration of propylene oxide.

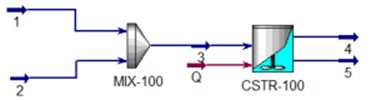

Make the PFD as shown below. The

way to input the reaction in the reactor operation is the same as in the

conversion reactor. To enter the reactor volume, click on Rating → Sizing.

Since the reactor operates in an

isothermal state (25 OC), on the worksheet enter 25 oC for stream temperature 5 or 4.

Reaction conversion can be seen

on the Reaction → Result

tab.

After converging try to increase

the reaction temperature to 75 oC, then check the conversion

of the reaction.

4. Ideal PFR (Plug Flow Reactor) Reactor

In addition to the CSTR reactor,

another type of reactor commonly used in industry is the PFR. This reactor is

composed of a cylindrical pipe and normally operates in a steady state like the

CSTR reactor. PFR reactors are generally used for reactions in the gas phase.

The PFR reactor describes the

chemical reaction process in pipe flow without mixing. This reactor assumes

that reactions occur in sequential order as materials pass through the reactor.

This reactor is suitable for reactions with fast reaction kinetics and

sequential reactions. In the PFR simulation with HYSYS, the reaction types that

can be selected are kinetic and heterogeneous catalysis. Just like in CSTR, the

conversion value of the PFR reactor is also affected by the reactor volume, so

information about the reactor geometry must be provided.

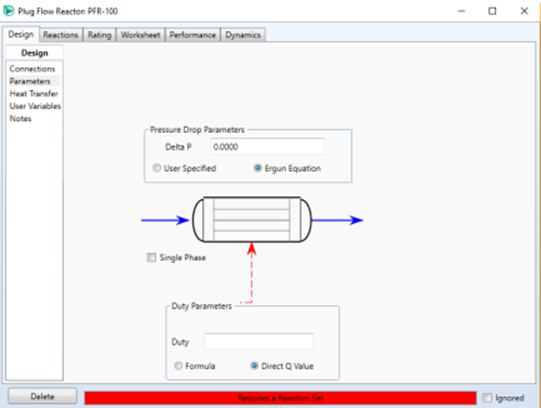

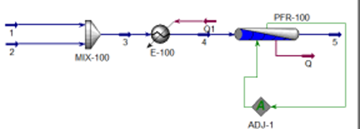

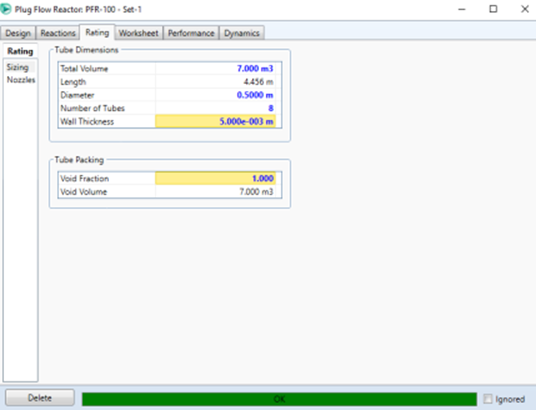

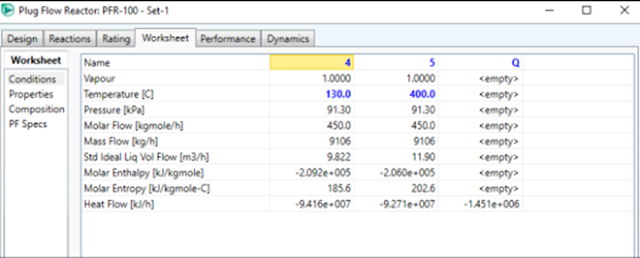

For the reaction below, the

selected reactor is PFR. The operating conditions of the reactor are set at

400°C, and the pressure drop of the reactor is calculated by Ergun's equation.

Before entering the reactor, the mixed feed stream is preheated to 130°C.

Initial feed conditions for CO were at 25°C, 101.3 kPa pressure, and 100 kmol/h

flow rate. While H2O is at a temperature of 120°C, pressure of 101.3 kPa, and

flow rate of 350 kmol/hour. The reactor volume used is 7 m3 with a diameter of

5 m and the number of tubes is 8. Choose NRTL as a fluid package and

Peng-Robinson as a vapor model.

The reaction kinetics data are

presented as follows:

Base: mole fraction of CO, with

rate unit kg mol/m3 s.

Forward reaction: A = 5.9 x

108, E = 1.2 x 105 kJ/kmol

Estimation of unavailable Binary

Interaction Parameters

Provide reaction input by first

selecting the reaction type Kinetics, and input as follows.

- Base: Mole Fraction

- Reaction Phase on Vapor phase

Pressure drop in the reactor can be input directly or can be estimated using the Ergun equation

Reactor geometry can be input as

follows Volume: 7 m3; Diameter 0.5 m; Number of Tubes: 8

Set the reactor exit temperature

at 400 oC

by giving a Stream

temperature input of 5.

When designing chemical processes

or trying to understand reaction kinetics, an understanding of the appropriate

reactor type is important. Aspen HYSYS provides a powerful tool for exploring

these different reactor types, and this is only a small selection of the

options available. The selection of the right reactor depends largely on the

type of reaction, kinetics, and operating conditions you are dealing with.